CIRCUMET

Advanced School on Circular Metal Components for the Swedish Manufacturing Industry

Latest news:

- Survey with industry for course content and teaching format finished in October 2023.

- Internal workshop is being arranged with CIRCUMET industrial partners to facilitate efficient co-production.

- Cooperation between university partners are initiated to arrange academic co-production for course development, as well as to innovative admission routines for professionals in the industry.

CIRCUMET aims at creating a comprehensive joint effort for developing 80-90 credits courses in advanced level on the topic of climate action in the metal component manufacturing industry. Flexible pedagogical methods and tailored admission routines will be developed for attracting professionals from the industry.

Course modules to be developed

Circularity

Courses included in this module:

- Introduction to Sustainability and Circularity*

- Material development for circularity and future trends*

- Component design for disassembly and recyclability*

- Science of remelting

- Applied Life Cycle Analysis (LCA)

* Courses starting Autumn 2025

High-Performance materials and components

Courses included in this module:

- Metallurgy of cast alloys

- Assessment and analysis of recycled materials and components

- Modelling and simulation for circular metal component manufacturing

- Design for minimal material utilization

- Functional materials selection and product innovation

Energy and resource-efficient manufacturing technology

Courses included in this module:

- Sustainable manufacturing for metal components*

- Data analysis-led process optimization

- Introduction to principles of Industry 4.0 & 5.0

* Course starting Autumn 2025

What happens next?

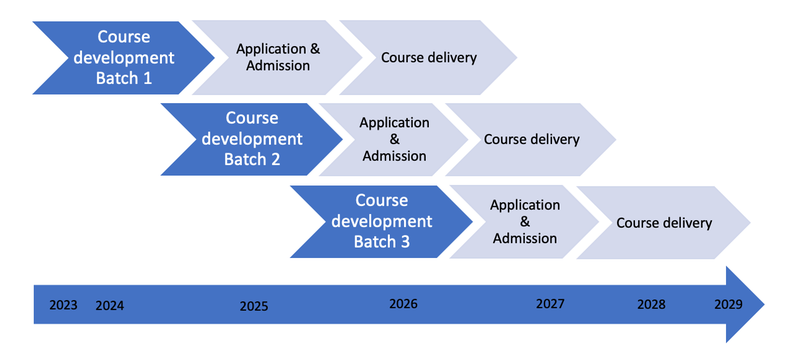

%20Circumet%20timeline.png)

In late 2023 and during 2024 courses will be decided, and planned, and the first batch of courses will start to be developed. The first batch of courses open for application will be released in spring 2025, and those courses will start in autumn 2025. Since we are at an early stage of the project, course format, application procedures and prerequisites are not yet set.

But do sign up above to receive information as soon as such is posted.

The CIRCUMET plan

Objective

- Create a joint effort for developing 80-90 credits courses at advanced level on the topic of climate action in the metal component manufacturing industry.

- Develop flexible pedagogical methods, and innovative admission/validation routines for effective competence supply for the professionals in the industry.

- Pilot-run the developed courses and accordingly fine-tune the methodologies and contents if needed.

- Plan and develop the industrial research school proposal on the climate action for the metal industry.

Importance of the project

Particularly in Sweden, the manufacturing industry is considered the backbone of the economy, with more than 13% contribution to the GDP, and the metal component manufacturing industry is among the top sectors. Yet manufacturing sector has an outsized impact on the environment with around 20-25% direct CO2 emissions.

On the other hand, there are very limited and, in most cases, scattered educational packages related to climate action in the metal component manufacturing industry. This highlights the urgency and importance of developing tailored and flexible competence supply in both academia and industry, in order to effectively fight against climate change in the metal component manufacturing sector.

Expected results

The effort covers the circularity and sustainability in the entire value chain of metal component manufacturing; from component design optimization, to manufacturing processes, material selection, and even after the component lifetime. Important topics such as Digitalization, Life cycle analysis, and Business models in circular metal component manufacturing are embedded within the project scope.

This is in-line with many industrial sectors’ commitment to the business ambition for a 1.5˚C goal, which targets a climate-neutral and circular business by 2040. The Swedish “Riksdag” also has a clear goal in this regard: by latest 2045, Sweden must have no net emission of greenhouse gasses to subsequently achieve negative emissions.

Project team

Financier: KK-Stiftelsen External link, opens in new window.

External link, opens in new window.

Duration of the project: 2023-2029

Management team:

Ehsan Ghassemali, Assoc. Prof. JTH

Johan Ahlström External link, opens in new window., Prof. Chalmers

External link, opens in new window., Prof. Chalmers

Madelene Zetterlind, Pedagogical developer, JTH

Stefan Brolin External link, opens in new window., External relations, JTH

External link, opens in new window., External relations, JTH

Industrial Partners:

GKN Aerospace Sweden, Sandvik Coromant, Fagerhult, Husqvarna Group, Scania CV, Volvo Cars, Comptech, AGES Industri, Ovako, Stena Metal International, Gjuteriföreningen, Jernkontoret, Svenskt Aluminium, Tunga Fordon, Fordonskomponentgruppen

Contact us

We would be glad to hear your opinion and suggestions:

Project leader: Ehsan Ghassemali

Deputy leader: Johan Ahlström (Chalmers) External link, opens in new window.

External link, opens in new window.

Pedagogcal developer: Madelene Zetterlind External link, opens in new window.

External link, opens in new window.

Marketing and communication: Stefan Brolin, Linda Bergqvist Opens in new window.

Opens in new window.