Melting furnaces and casting

Our department's core expertise lies in the melting and casting of metals, a field in which we are exceptionally well-equipped. The JU-CAST laboratory houses a diverse range of advanced furnaces and specialized casting facilities, enabling cutting-edge research and innovation in foundry technology.

Open induction furnace (up to 80 kg)

- Supplier & Model: Marx / MMTO-Fe-80-100/2000

- Type of Material for melting: Specialized for Ferrous alloys

- Melting method: Induction (MF-transistor technology)

- Max temperature with actual linning materials: 1600C

- Power: 100 kW

- Melting capacity: 80 kg (about 40 min melting)

- Main connections: 3x 400V, 50 Hz

There is a smaller induction furnace (up to a 7 kg); MINAC 25/40 induction heater

Closed induction melting furnace (vertical)

- Supplier & Model: Entech / ETF 50 16-V

- Heating method: Induction

- Max temperature: 1600C (other version available for up to 1700C)

- Effect: 4800-6000 VA

- Connection: 400V, AC

Also used for heat treatment and can be adapted with some protective atmosphere during heating.

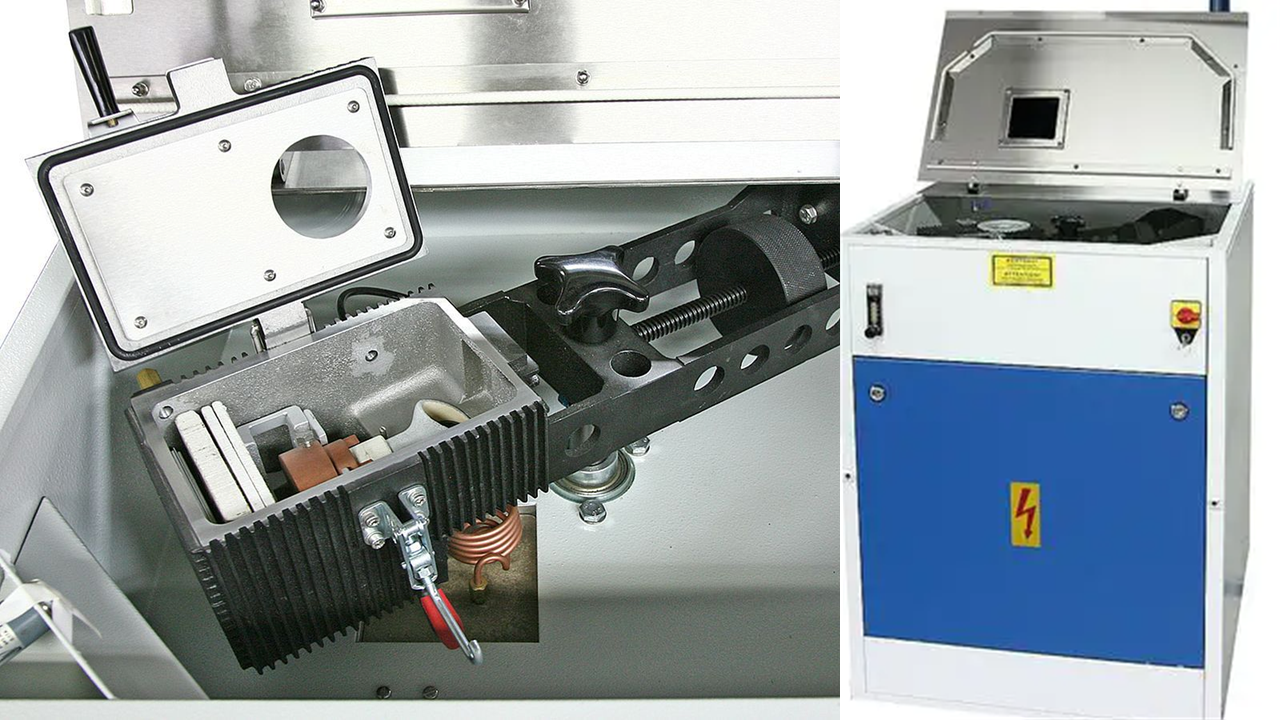

Vacuum Induction Melting furnace

Including centrifugal casting under protective environment.

- Supplier & Model: Linn High Temp / Lifumat-M-2000-6,6-Vac

- Type of Material for melting: All metals

- Melting method: Induction (High frequency)

- Potective gas flow: up to 5 l/min

- Max admissible protective gas pressure: 2.5 bar

- Power: Voltage: 3 x 400 V; max 16 kVA

- Max melt weight: Fe: 750 gr, Al: 300 gr

- Crucible: Cermic or graphite

- Temperature reading: Pyrometer

Possibility for centrifugal casting under protective environment with rotation speed of up to 500 rpm.

High Pressure Die Casting (incl melting furnace)

- Supplier & Model: SFV-50A

- Type of Material for melting: Aluminium

- Plunger speed: 50-2000 mm/s

- Max die clamping stroke: 340 mm

- Locking force capacity: 100 kN

- Al casting weight range: 0.8 to 2.5 kg

Including a resistance furnace of up to 200 kg Al melt (up to 900C melt temperature). Adaptable for semi-solid casting, including semi-solid production unit.

Resistance melting furnace (tilting capability)

- Supplier & Model: Naertherm / K4/13

- Type of Material for melting: Specialized for non-Ferrous alloys

- Melting method: Resistance heating

- Max temperature: 1300C

- Power: 100 kW

- Melting capacity: ~6 kg for Aluminium

Possibility of tilting for casting.

Directional solidification furnace

To replicate the various cooling rates during solidification, leading to various microstructural coursenesses.

- Supplier & Model: Entech / built in-house

- Type of Material for melting: Al and light alloys

- Min withdrawal rate: 0.03 mm/s

- Max withdrawal rate: 6 mm/s

- Melting capacity: up to three rods of 15 mm height and ~10 mm diameter

- Protective environment during melting/solidification: Ar gas