Materials and Manufacturing

Our research in the area of materials and manufacturing concerns material properties and manufacturing processes for cast materials.

The department of materials and manufacturing is a vibrant multidisciplinary research environment that advances the state of the art knowledge and fosters the development of highly skilled researchers and professionals.Our research focuses on material properties and manufacturing processes for cast components.

The work is based on the understanding and control of materials microstructures and mechanical and physical properties behavior. The purpose of our research is to develop knowledge about the relation between material composition, melt quality, process, geometry and defect formation as well as their relation to the mechanical and physical properties; from the materials design to the process to component in use. The research method is a holist approach to the full chain of component manufacturing: a synergetic approach includes alloy design, manufacturing process, post treatments, microstructure study, properties characterization, finishing treatments, and modelling of local performances with the final aim to implement the results into design tools.

The department cooperates with various national and international research institutions and industrial partners, and is engaged in basic and applied research projects. Coproduction with industrial partners is a strong characteristic of our project portfolio, both with large companies and SME. In this framework, the core research has 6 main directions.

Below you can find a short description of each research direction and the main contact person for each direction, who acts also as a coordinator.

Testing and Analysis Capabilities

Our capability to perform experiments, measure mechanical and physical properties and study microstructure is fundamental to our research. To study the complex relationships between material properties, microstructure, manufacturing process and component design we use a wide range of equipment.

Research Directions

- Professor Foundry Technology

- School of Engineering

- attila.dioszegi@ju.se

- +46 36-10 1656

Cast Iron is the most used metallic alloy for creating complex shaped items used in all industrial sectors (automotive, energy, communication, engineering). Cast Iron is also one of the few technical alloys recyclable 100% having a small footprint on our living environment and enable a full circular economy.

The research area is interdisciplinary and include all ferrous cast alloys with focus on lamellar, compacted, and nodular cast iron produced in both sand and permanent moulds. Phenomenon connected to the casting production process, such the mould and core making, liquid metallurgy, melt treatment, mould filling, interaction between the moulding material – mould atmosphere – molten metal, nucleation and inoculation, solidification and crystal growth, volume change, inter-dendritic flow and defect formation mechanisms are included in the research area.

An important activity in this research area is the study of morphology formation and its relation to final thermal and mechanical properties. Both static and dynamic tensile properties are covered.

Numerical modelling using deterministic approaches to predict material and defect formation as well the simulation of the casting process plays a central role in the research area. Importance is dedicated for thermal analyses aiming to connect observed phenomenon to thermal processes and predict casting properties in the production process as well to determine thermo-physical and thermo-mechanical properties as input for casting simulation.

Advances in this research area are strictly dependent on innovative own developed research instruments and a frequent experimental activity in foundry plants.

- Professor Materials and Manufacturing - Casting

- School of Engineering

- anders.jarfors@ju.se

- +46 36-10 1651

Aluminium and Light Alloys

The primary activity for the aluminium and light alloys research is to pave the way to enable material descriptions and models to allow process simulation and use of local properties for both design and process simulation for cast components. For wrought materials strength and ductility response on process conditions are critical to understand processability, formability and performance of a component.

The work focuses on the use of both primary and secondary aluminium alloys to support a sustainable development of the foundry industry and the use of magnesium alloys. The work focus on the formation of the microstructure in existing and new casting and forming processes. The description of the mechanical properties based on the microstructures are also part of the core activity. This relates to both thermo-physical properties and mechanical properties. The end game is to gather data and develop descriptions allowing for life-span prediction of the cast and wrought components in use. Imperative to the area is also the development of the actual casting and forming process and tool development as these strongly influence the component properties and the industry must be prepared for this. Working towards processes that are zero or near zero emission processes that are capable of producing sound components using recycled materials with a high material efficiency and zero or near zero material losses.

- Professor Materials and Manufacturing - Casting

- School of Engineering

- ehsan.ghassemali@ju.se

- +46 36-10 1692

Alloy Development

This research direction specializes in the design and development of durable alloys tailored to perform in diverse and challenging environments, including (but not limited to) high-temperature conditions, to highly mechanically loaded conditions, to corrosive environments, and hydrogen-rich atmospheres. We serve a broad spectrum of industries, including aerospace, automotive, gardening tools, and others that depend on high-performance metallic materials and components. Our expertise spans a wide range of alloy systems, including magnesium (Mg), aluminum (Al), Steel, Titanium (Ti), Cast iron, Superalloys, and emerging materials such as High-entropy alloys or Multi-principal element alloys.

A cornerstone of our work lies in integrating theoretical modeling (incl. machine learning and AI) and computational thermodynamics to design alloys and assess their processability. This is complemented by experimental processing, followed by rigorous testing and characterization under near-to-real working conditions. While we specialize in cast alloys, our competence extends to wrought alloys, ensuring a holistic approach to alloy development. Recognizing the growing industrial demand for sustainability, we actively focus on creating recyclable and resource-tolerant alloys, embedding sustainability and circularity principles within our alloy design strategies.

Through this interdisciplinary approach, we aim to provide innovative, sustainable solutions for the modern challenges faced by industries, paving the way for materials that meet the demands of performance, durability, and environmental responsibility. We are committed to driving advancements in alloy development that contribute to a more sustainable and efficient future for metal industries worldwide.

- Professor surface technology

- School of Engineering

- caterina.zanella@ju.se

- +46 36-10 1691

Surface Technology

The research direction Surface technology deals with the surface properties of materials. Surface treatments for functional or aesthetical purpose are considered and optimized. Surface treatments are considered in different aspects, from the process parameters to the compatibility of the process and material to the substrate, from the pretreatment to the final characterization. Process parameters are linked to the surface microstructure and final surface properties. Corrosion resistance as well mechanical properties of the surface can be tested and tailored.

Special focus is given to electrochemical process of the surfaces, both in term of corrosion resistance of metals but also as protection treatments as anodizing and electroplating.

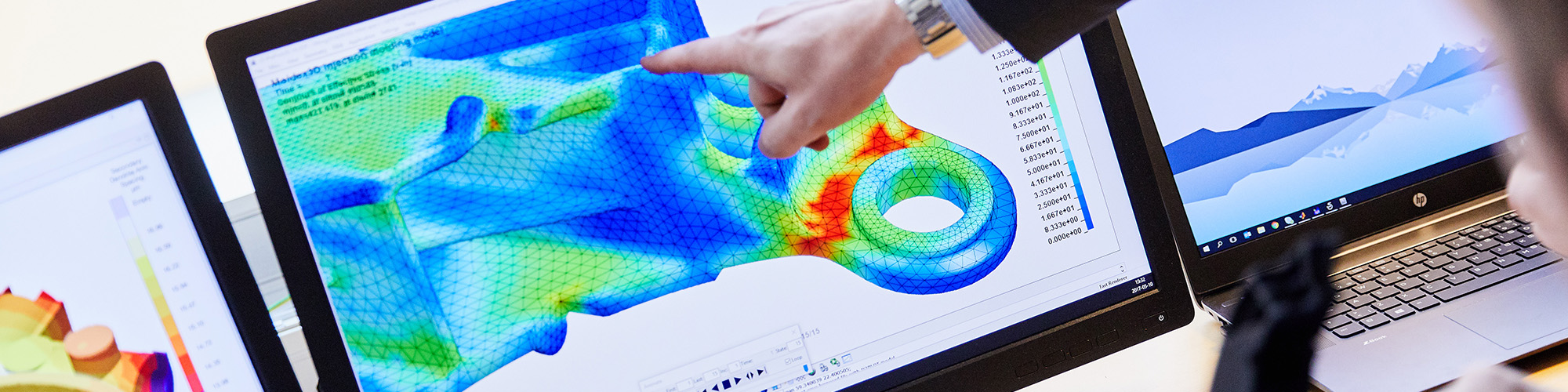

Simulation Technology

In the research direction Simulation Technology, research is conducted within topics as microstructure modelling, material characterization, casting process simulation, load analyses (FEM) and geometry optimization. These topics are all treated as a part of a closed chain of simulations for cast components, where different types of simulations on multiple scale levels can be utilized and combined. Examples of numerical techniques and simulations that are done include mathematical modelling of casting and solidification, casting process simulations, FE simulations of 2D and 3D microstructures as well as load analyses of cast components in use.

Contact person: Associate Prof. Jakob Olofsson; jakob.olofsson@ju.se

Staff

Department of Materials and Manufacturing

- Professor

- School of Engineering

- peter.leisner@ju.se

- +46 36-10 1685

- Leave of absence

- Assistant Professor

- School of Engineering

- donya.ahmadkhaniha@ju.se

- +46 36-10 1658

- Acting Senior Lecturer

- School of Engineering

- nils-eric.andersson@ju.se

- +46 36-10 1657

- Postdoc

- School of Engineering

- guilherme.antonelli.martiniano@ju.se

- Senior Lecturer

- School of Engineering

- ilia.belov@ju.se

- +46 36-10 1686

- Laboratory Engineer

- School of Engineering

- jorgen.bloom@ju.se

- +46 36-10 1683

- Assistant Professor

- School of Engineering

- toni.bogdanoff@ju.se

- +46 36-10 1653

- Assistant Professor

- School of Engineering

- lucian-vasile.diaconu@ju.se

- +46 36-10 1289

- Professor

- School of Engineering

- attila.dioszegi@ju.se

- +46 36-10 1656

- Research Fellow

- School of Engineering

- bjorn.domeij@ju.se

- +46 36-10 1602

- Researcher

- School of Engineering

- vasilios.fourlakidis@ju.se

- +46 36-550 2477

- Professor

- School of Engineering

- ehsan.ghassemali@ju.se

- +46 36-10 1692

- Leave of absence

- Doctoral Student

- School of Engineering

- claudia.guedes@ju.se

- +46 36-10 1603

- Professor

- School of Engineering

- peter.hansbo@ju.se

- Doctoral Student

- School of Engineering

- abdullah.harazeen@ju.se

- +46 36-550 2414

- Postdoc

- School of Engineering

- yyu-chin.huang@ju.se

- +46 36-10 1538

- Professor

- School of Engineering

- anders.jarfors@ju.se

- +46 36-10 1651

- Doctoral Student

- School of Engineering

- jeevan.joseph@ju.se

- +46 36-10 1369

- Doctoral Student

- School of Engineering

- sujith.subhash@ju.se

- Doctoral Student

- School of Engineering

- deepak.kolli@ju.se

- Leave of absence

- Assistant Professor

- School of Engineering

- lucia.lattanzi@ju.se

- +46 36-10 1509

- Associate Professor

- School of Engineering

- taishi.matsushita@ju.se

- +46 36-10 1697

- Postdoc

- School of Engineering

- alireza.nazarahari@ju.se

- +46 36-10 1584

- Laboratory Engineer

- School of Engineering

- esbjorn.ollas@ju.se

- +46 36-10 1684

- Head of Department

- School of Engineering

- jakob.olofsson@ju.se

- +46 36-10 1659

- Assistant Professor

- School of Engineering

- muhammad.qadeer@ju.se

- +46 36-10 1540

- Leave of absence

- Doctoral Student

- School of Engineering

- ricardo.queiros@ju.se

- +46 36-10 1091

- Doctoral Student

- School of Engineering

- namrata.sarania@ju.se

- Research Engineer

- School of Engineering

- aastha.sharma@ju.se

- +46 36-10 1592

- Research Engineer

- School of Engineering

- jacob.steggo@ju.se

- +46 36-10 1553

- Postdoc

- School of Engineering

- dinesh.sundaram@ju.se

- +46 36-10 1751

- Associate Professor

- School of Engineering

- magnus.wessen@ju.se

- Professor

- School of Engineering

- caterina.zanella@ju.se

- +46 36-10 1691

- Postdoc

- School of Engineering

- qing.zhang@ju.se

- +46 36-10 1796

Projects

Ongoing Research Projects

- Al-MMC (ProForAl) - Egenskaper och formbarhet hos Al-SiCp MMC

- ALL4HYDRO II - Legeringsutveckling för väterelaterade applikationer

- Augmented Lagrangian Methods

- Balbas - Bränslecell med Aluminium som basmaterial

- CIRCUMET - CIRCULAR METAL COMPONENTS FOR SWEDISH MANUFACTURING INDUSTRY: COMPETENCE DEVELOPMENT ON THE MAST

- Cleancon II - Clean Construction Machinery External link, opens in new window. - Främja användningen av nollemissionsarbetsmaskiner inom bygg- och anläggningsprojekt och kommunal drift samt driva på marknaden genom upphandling och dialog inom hela aktörskedjan.

- ClimAl (ALSCRAM2) - Secondary Al for sheetmetalforming

- DEC-HEF (Design and ElectroCrystallization of High Entropy thin Films)

- EICAl - corrosion fatigue of recycled Al

- EVIDENT

- Grönt ljus - Genom ökad rörlighet mellan Fagerhult och JTH är projektets mål att identifiera nya material och processer för ersättning av komponenter med hög klimatpåverkan.

- HEeGg - Hållbart och Energieffektivt Gjutgods - Projektet syftar till att utveckla metoder för att använda återvunnen aluminium för kostnadseffektiv tillverkning av komponenter. Verifieringstekniker kvalitetssäkrar den smälta metallen inför gjutning för att tillverka återvunna komponenter med hög och jämn kvalitet. Projektet har goda möjligheter att öka resurseffektiviteten genom att recirkulera aluminium och öka återvinningsgraden.

- IFT: JÖNKÖPING

- SANDRA (Hållbar och cirkulär SANDåtervinning)

Completed Research Projects

- InREAL

- KliRAl - Climate adapted purified Aluminium

- LCF-PP - Low carbon footprint Polypropylene for sustainable development and circular economy

- LISA - Low Impact of Sustainable Aluminium

- LOWEAR - Low density, wear-resistant Fe-based alloy development

- MaReAl - Manufacturing of Al-MMC brake discs from recycled Al-Si alloys.

- PolyComp - Lektor inom polymerer och polymerkompositer – strategisk rekrytering

- RECASTing - RECycling steel Alloys to develop sustainable high performance high-entropy STeels

- RESA - Reducerad elanvändning i smälthanteringsprocessen hos aluminiumgjuterier

.png)

%20(1).png)