ClimAI- Climatesmart high-performance aluminium sheets

Facts

Academic Partner: School of Engineering

Industrial Partners:

Polestar Automotive Sweden AB, Gränges Finspång AB, Stena Metall AB, AP&T Sweden AB, RISE Research Institutes of Sweden AB

Duration of the project: 2022-2025

Team of researchers:

Anders Jarfors, Professor

Ehsan Ghassemali, Associate Professor

How to design an alloy and processing route for a trace element resilient manufacturing of high-performance components

Introduction

The project targets three main problem areas

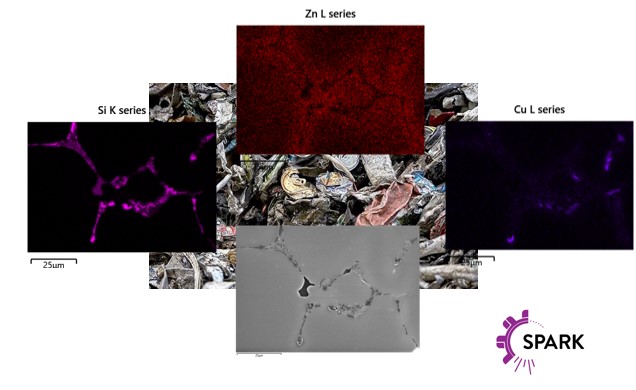

- Analyse and identify critical trace elements affecting recrystallization and strain hardening with particular focus on "cocktail effects"

- Develop and test alloying principles to increase the use of secondary aluminium sources for a rolled product for appropriate demonstrators to meet the requirements of

- Broaden the number of available aluminium alloys whose specifications readily accept recycled metal and work well in high-quality, refined products with a minimum of climate impact.

Purpose

The aim is to enable a wider application of sheet metal based on secondary aluminium as this leads to a significantly reduced associated carbon footprint. Furthermore, the possibilities for new ways of procuring raw materials can increase.

The main goal lies within increased resource efficiency, especially through process innovation that affects objective 5A and 5D. The use of secondary materials will also affect stage 6 with reduced environmental impact significantly through a reduced need for material downgrading and better use of scrap with an indirect impact on 6G.

Expected results

By being inspired by Polestar's idea of striving towards a Zero CO2-footprint offers aluminium sheet-based components offer a challenge as recycled metal gives reduced formability. The expected result is a combination of a process route and alloying principles that offer suitable levels of castability and rollability. The alloys and a process route through hot forming must provide a formability and component properties that are acceptable to and the users, together with a robust process route with good tolerance for trace elements.

For more information

- Professor Materials and Manufacturing - Casting

- School of Engineering

- anders.jarfors@ju.se

- +46 36-10 1651

Are you interested in a future collaboration?

- External Relations Manager

- School of Engineering

- linda.bergqvist@ju.se

- +46 36-10 1074