SCALABLE

Facts

Academic Partner: School of Engineering at Jönköping University

Industrial Partners: GKN Aerospace AB, Härdservice Norden AB

Project duriation: 2025-01 — 2026-12

Research team:

Alireza Nazarahari, Postdoc (Project leader)

Ehsan Ghassemali, Professor

Financier/s: KK-stiftelsen

%20morkbla-logo.png)

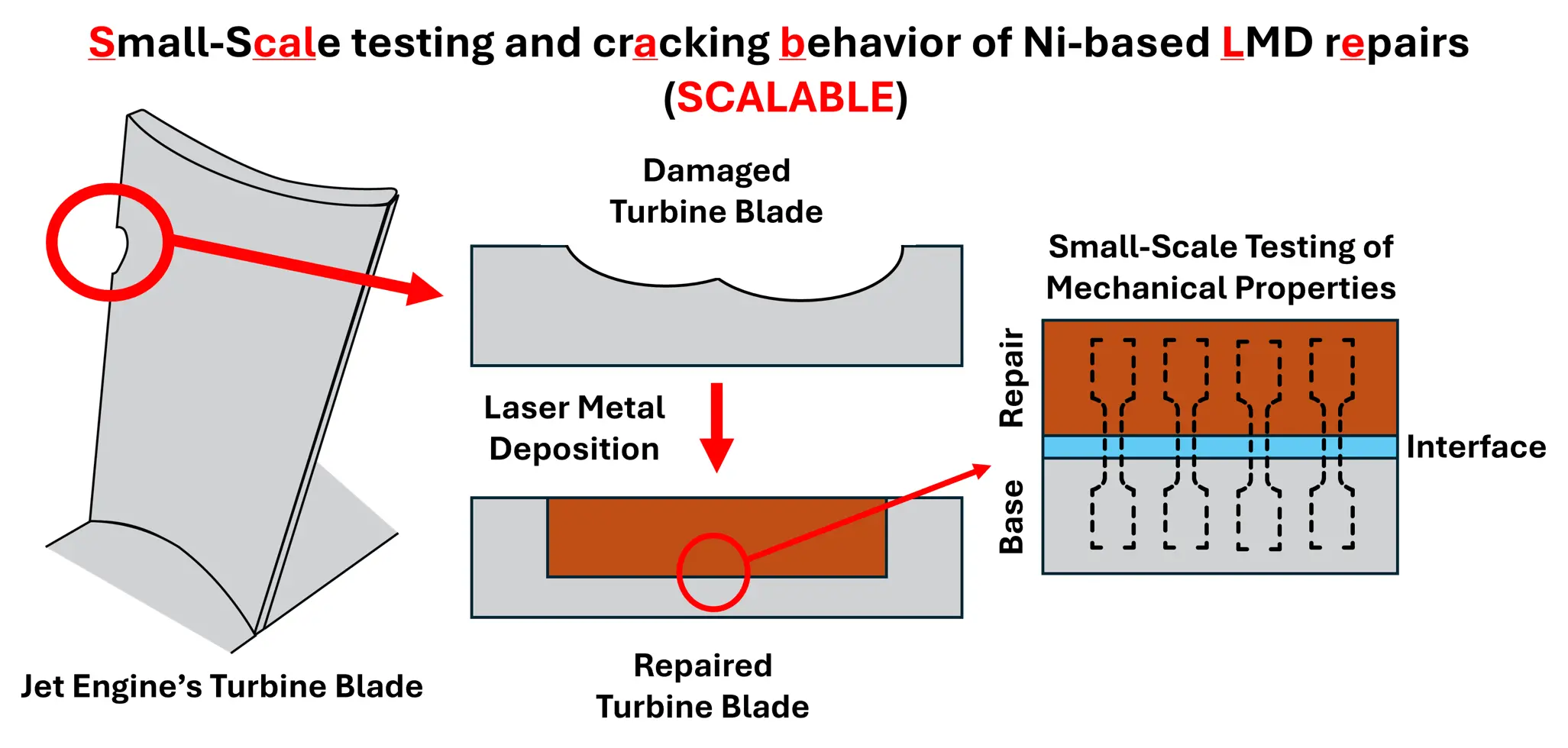

Small scale testing and cracking behavior of Ni-based LMD repairs

Introduction

Repairing aerospace components cuts CO₂ emissions and lowers industry maintenance costs. In SCALABLE, we aim to gain the necessary knowledge for reliable mechanical testing of Ni-based superalloy components.

Nickel-based superalloys are widely used in aerospace engines, and a reliable repair of such components is important for reducing costs and downtime in the aerospace industry. With recent progress in additive manufacturing, methods like Laser Metal Deposition (LMD) offer new repair processing routes. In the SCALABLE project, we aim to evaluate the reliability of repairs made by LMD. We will use in-situ miniaturized tensile testing (MTT) and miniaturized low-cycle fatigue testing to study the effect of repair microstructure on the mechanical properties of repairs. Moreover, our aim is to utilize heat treatments as a way to improve the properties of the repaired components.

Importance of project

To perform a reliable repair of components functioning in high-temperature and harsh environments, it is necessary to understand the effect of additively manufactured microstructure on the mechanical properties of the repaired region. This knowledge provides the necessary insight into how such components can undergo mechanical failure and how to extend the lifetime of a component. Moreover, heat treatments can be used to enhance the properties of LMD repairs and further extend the lifetime of a component.

Expected results / impact of the project

We expect the results of this project to help the aerospace industry carry out more reliable mechanical testing. Our goal is also to demonstrate that small-scale testing is a suitable method for evaluating the mechanical properties of non-homogeneous metallic components, such as those repaired with LMD. This approach improves testing accuracy and reduces the risk of misinterpreting material behavior.

For more information

- Postdoc

- School of Engineering

- alireza.nazarahari@ju.se

- +46 36-10 1584

Are you interested in a future collaboration?

- External Relations Manager

- School of Engineering

- linda.bergqvist@ju.se

- +46 36-10 1074