ProForAl

Fakta

Academic Partner: School of Engineering

Industrial Partners: Comptech, AC Floby, Gränges, Husqvarna

Duration of the Project: 2021-2023

Researcher:

Reference group:

Ehsan Ghassemali, Associate Professor

The automotive industry is facing ever increasing requirements for reduced emissions, reduced fuel consumption and increased electrification. In this context, one solution is to use more light-weight components. The aim of this research project is to develop an optimized light-weight material, which has the right mechanical characteristics for automotive applications.

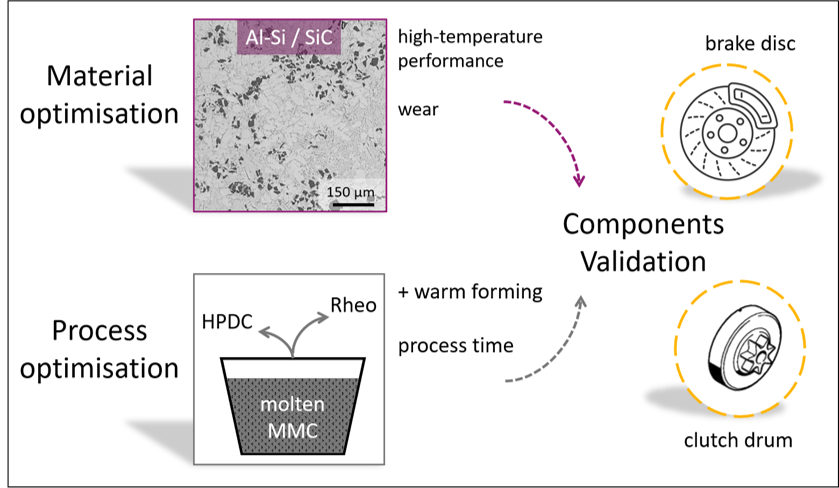

Alloys based on aluminium and silicon, which have been reinforced with microparticles of hard carbide (Al-SiCp composites), is a kind of light-weight material that has a great potential to meet future demands for light and wear-resistant components. These materials are used already today, for instance in brake discs for vehicles, and can be used in clutch drums for vehicles and chainsaws. In these applications, safety and light weight are important aspects. The material must withstand high stresses at high temperatures and heavy wear.

There is a need to improve the performance of these materials and to increase the productivity of the manufacturing process.

Purpose

The research project ProForAl (Properties and formability of Al-SiCp MMCs) has two primary goals. One is to optimise the composition of the Al-SiCp composite to improve its performance at high temperatures. The other is to optimise the production method to increase the productivity and thereby reduce the manufacturing costs.

Impact of the project

The research area of the project is highly topical for the automotive industry, which needs to find new ways of reducing emissions from fuel-powered and hybrid cars as well as reducing the weight of electric cars.

The companies participating in the project represent the whole chain from melt preparation to manufacturing of the final products. They play a vital role in the Swedish automotive industry and will benefit in a direct way from the results generated in the project.

The knowledge produced in ProForAl will also be beneficial for other industries that produce components with similar requirements as in the automotive industry.

Further, the project will give an important contribution to the international research within this area. The results will serve as a basis for future research projects and add new content to education in the area of metallurgy and production processes.

Do you want to know more about the project?

Please contact Lucia Lattanzi, Postdoc at the School of Engineering, tel. 036-10 15 09, e-mail lucia.lattanzi@ju.se.

Do you want to develop the next project with us?

Please contact Linda Bergqvist, External Relations Manager at the School of Engineering, tel. 036-10 10 74, e-mail linda.bergqvist@ju.se.