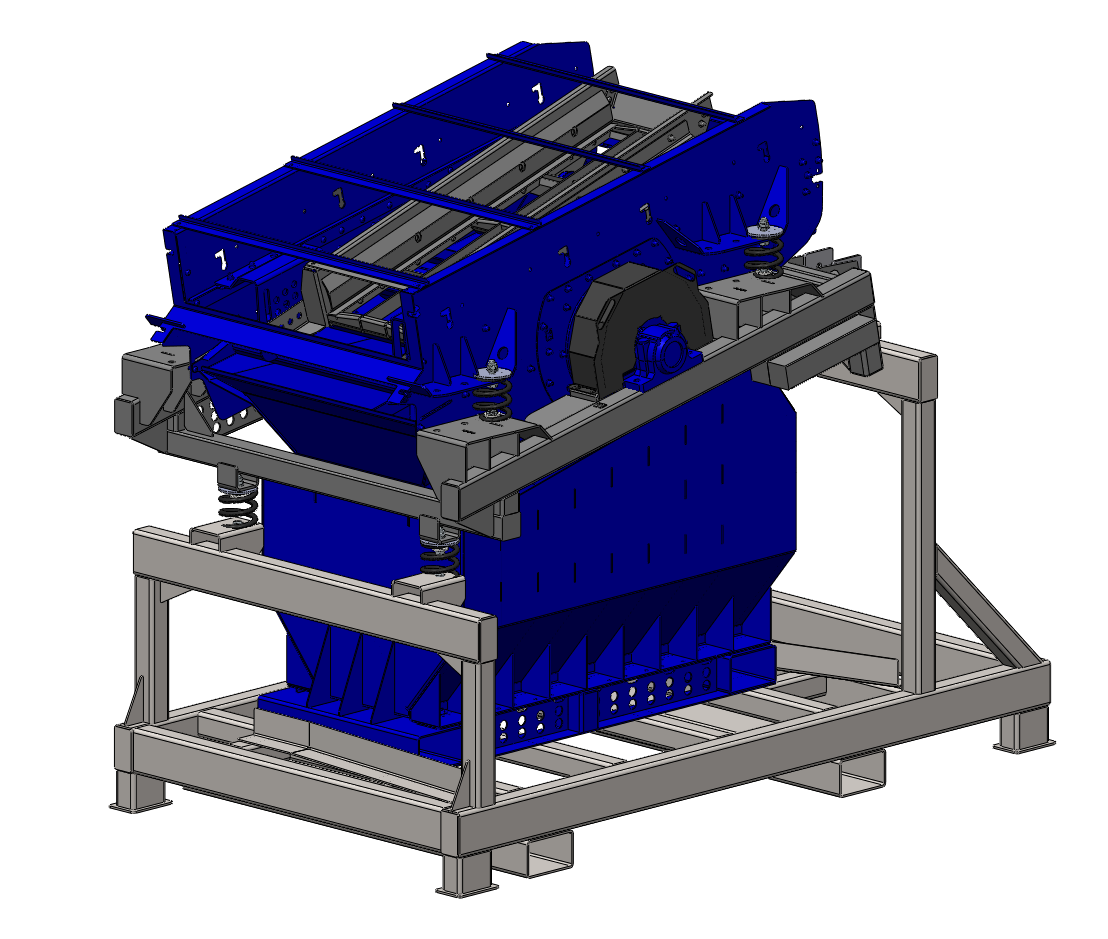

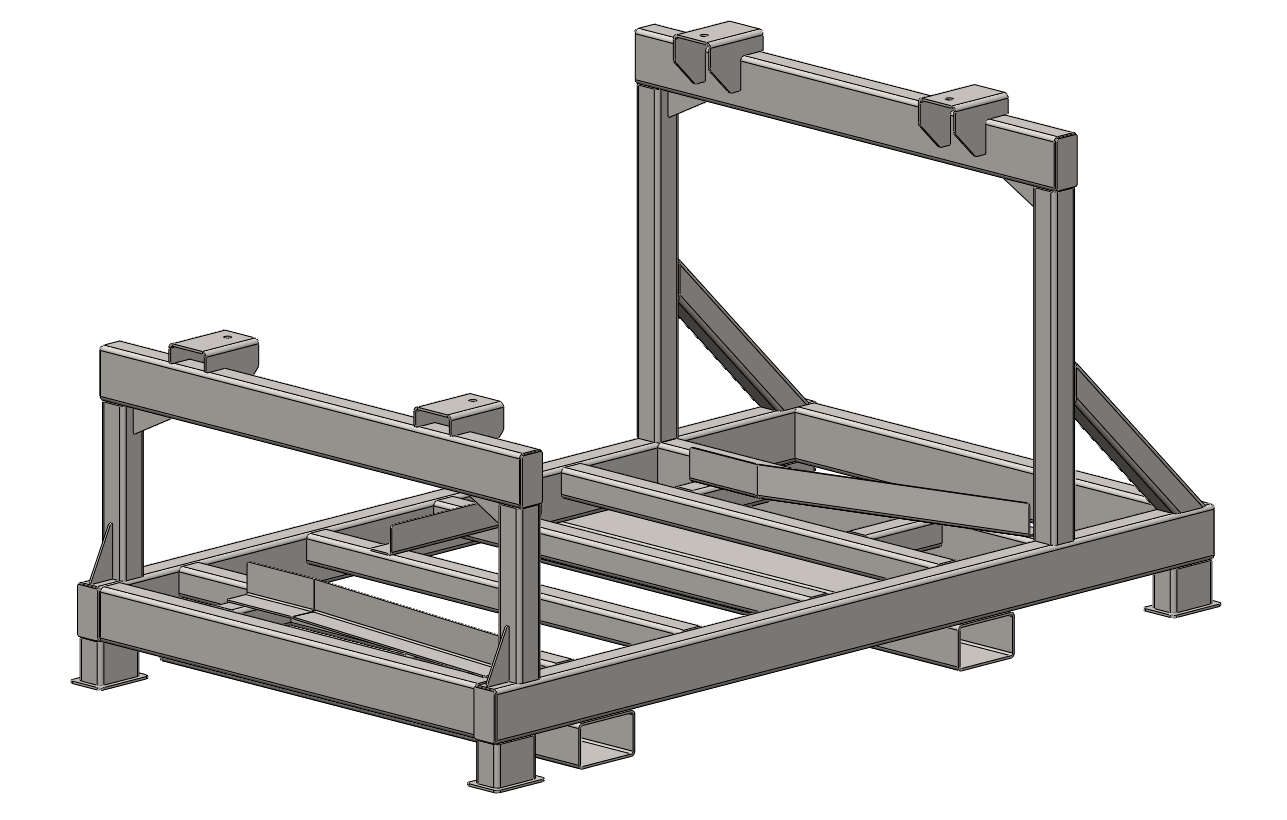

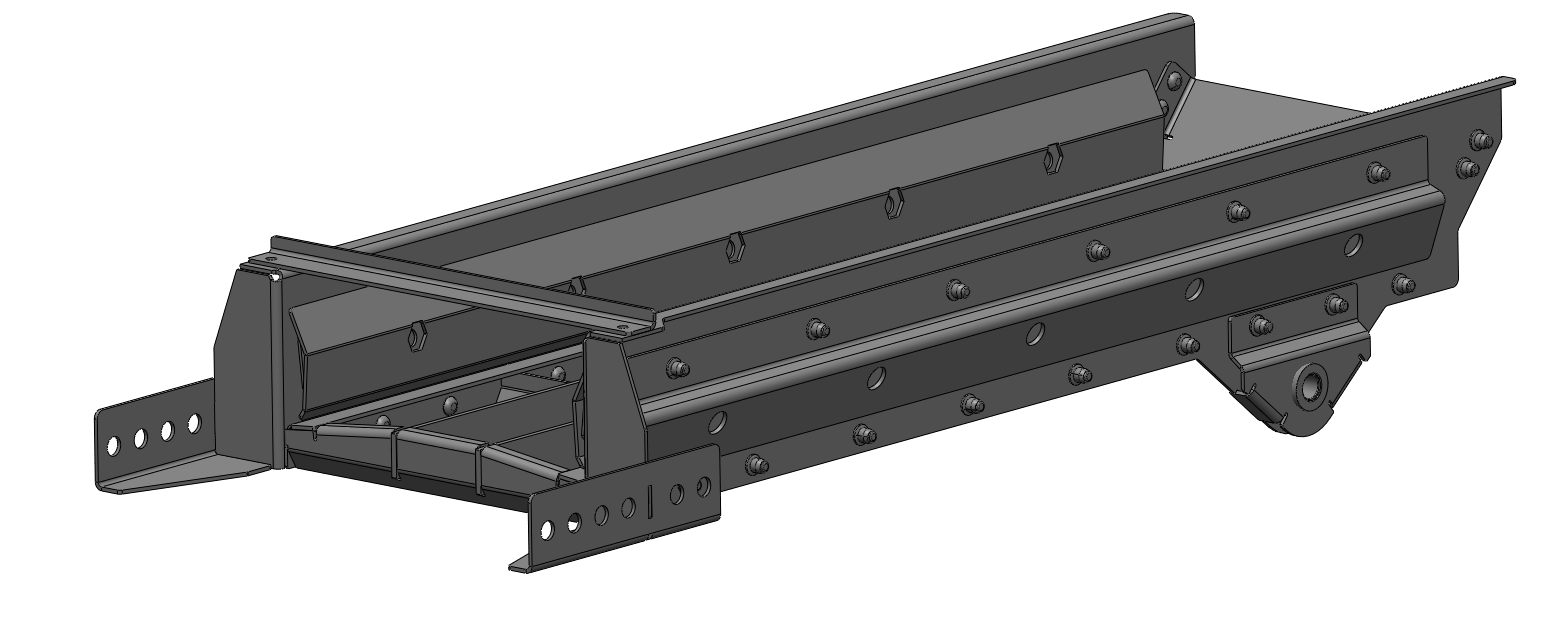

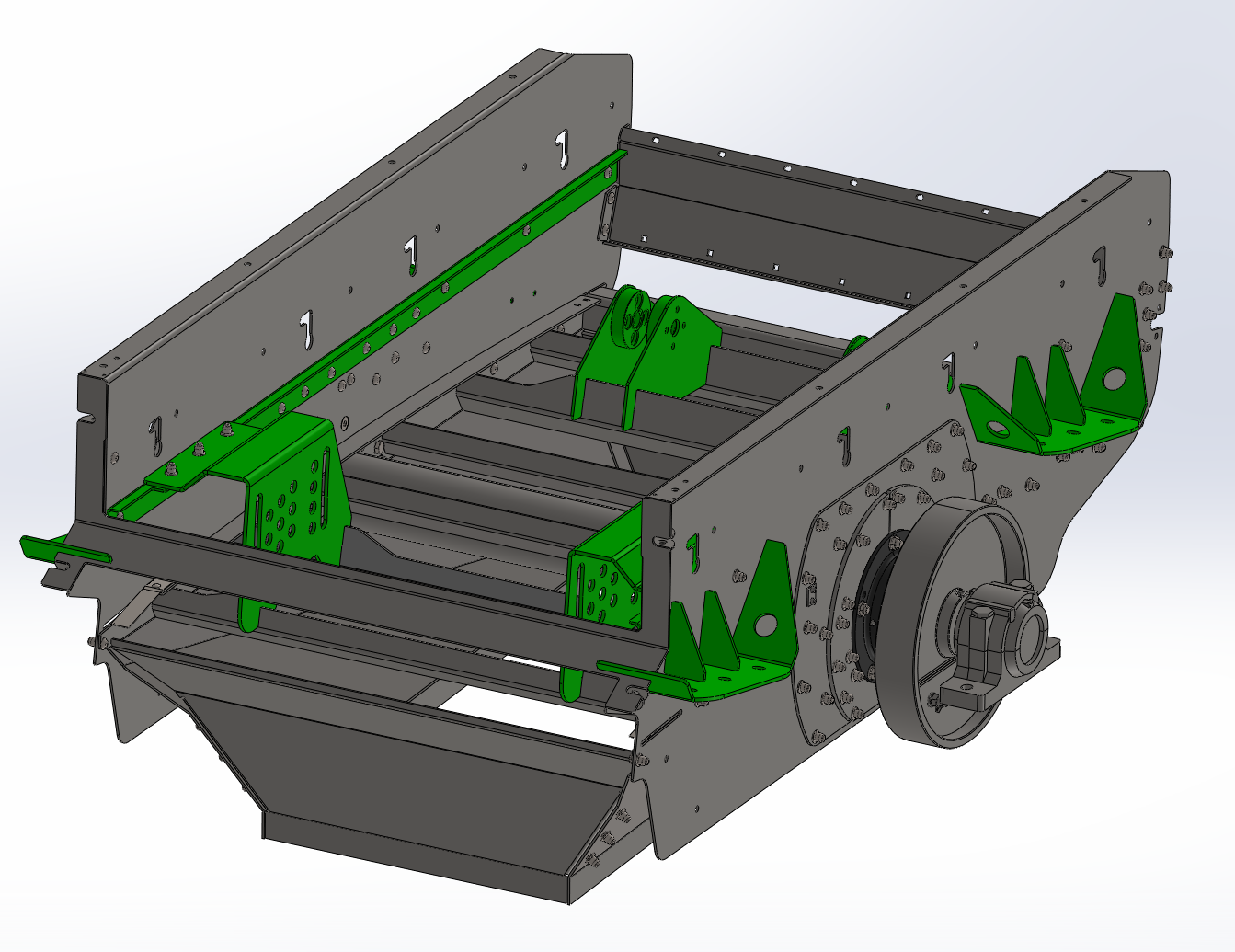

Construction of adjustable screening parameters

Maskin Mekano is a Jönköping based company who develops mainly screening equipment. To improve their product development process, they are very interested in how different governing factors of a screening plant affect the performance and quality of their machines.

Today, Maskin Mekano has well performing screening plants, but cannot accurately test how different governing parameters affect screening performance. Due to the size and cost of each machine, a traditional product development method with several different prototypes is untenable. We were therefore tasked with creating a machine which could test multiple of these governing factors on the same machine.

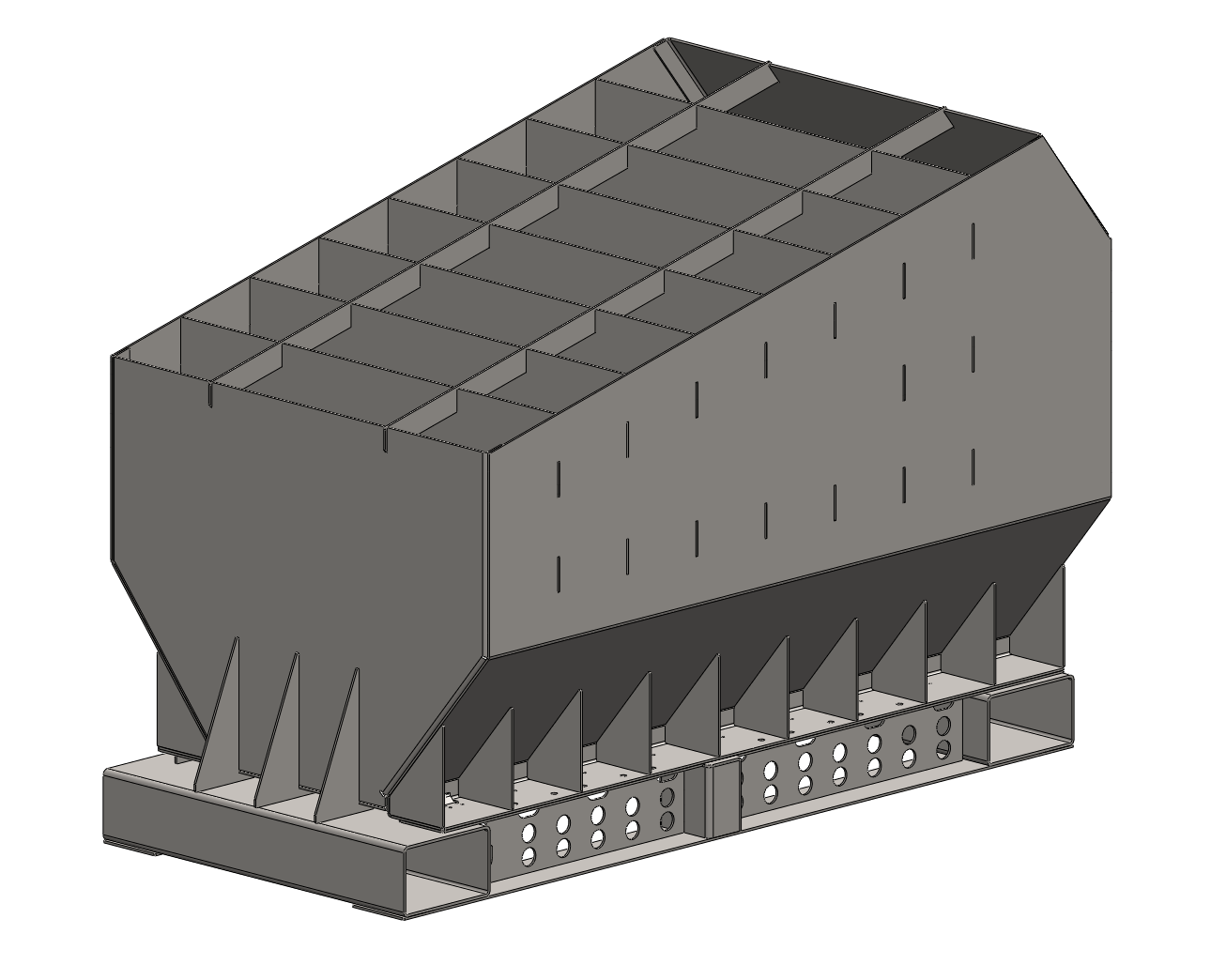

The project primarily involved creating a CAD model for an adjustable lab screen, focusing on several different parameters like the angle of the screening deck and the movement pattern of the screening box. The goal was to design a machine that could adjust these features and efficiently collect the sorted materials for evaluation. Extensive research was conducted on these parameters and their impact on screening performance. The work resulted in a manufacturing-specification CAD-model, mainly based on and customized from existing Maskin Mekano components, with newly designed parts where needed, and should be able to perform all requested tests. The work done also provided valuable insights into how the relevant governing parameters affect a screening plant's performance.