Investigating the Role of Product Flexibility in Production Systems

Emil Andersson

LinkedIn Länk till annan webbplats, öppnas i nytt fönster.

Wilhelm Lenz Gorner

A case study at a Swedish Automotive Manufacturer

The problem area of this thesis is concentrated on the uncertainty associated with introducing new products in production systems due to the adaptation to meet the sustainability goals in the automotive industry.

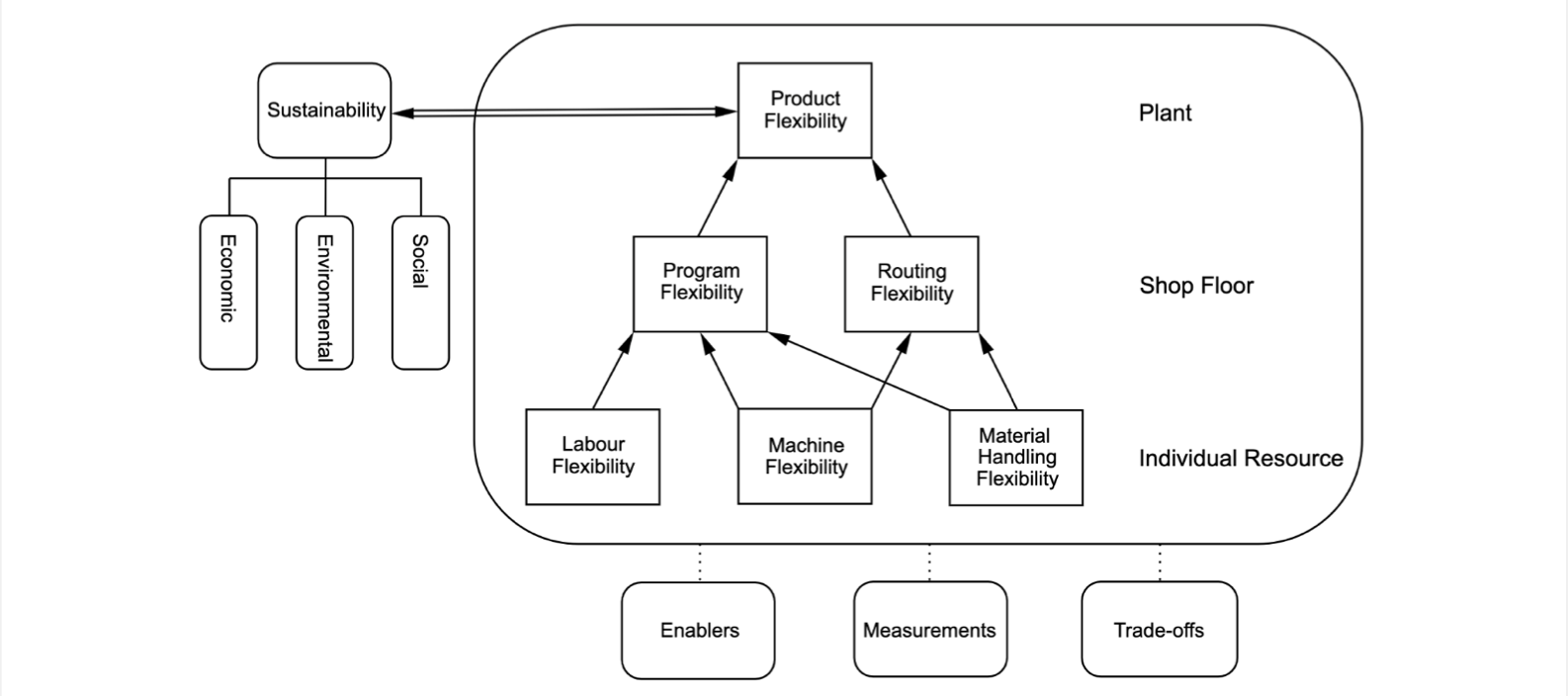

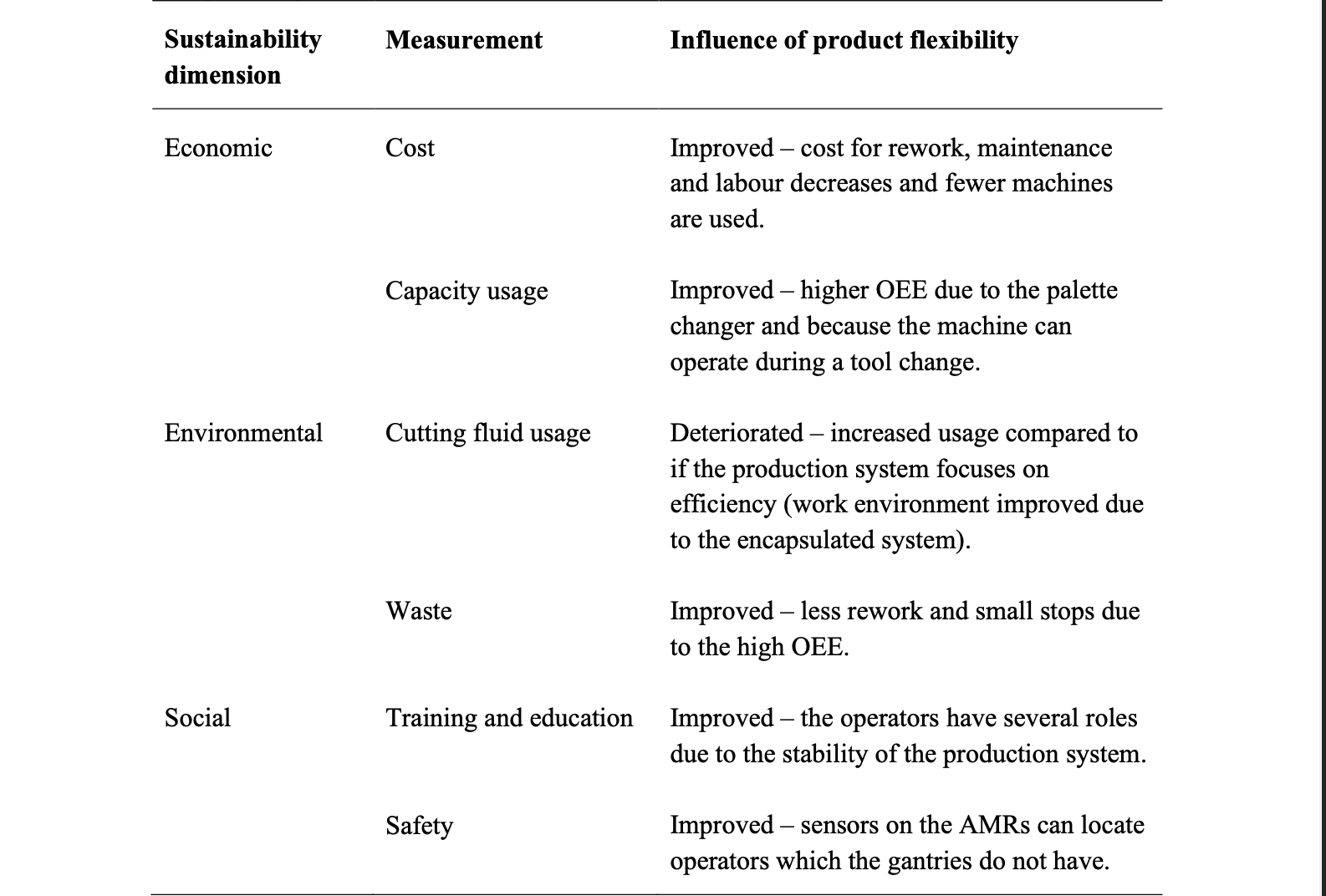

The urgency of sustainability has grown in recent years and the importance of reducing the use of fossil fuels and shifting to more sustainable energy sources is more evident than ever. The automotive industry is undergoing a shift to meet the demands of the future and this transformation also entails a high level of uncertainty, as it must deal with several factors that are unpredictable and complex. One of the key strategies to manage the uncertainty of introducing new products is the concept of product flexibility. The literature regarding product flexibility has been largely theoretical and more empirical research is therefore required for the subject. The purpose is therefore to investigate the role of product flexibility in production systems in the automotive industry to enable the green and electrical transition and to understand how product flexibility influences sustainability.

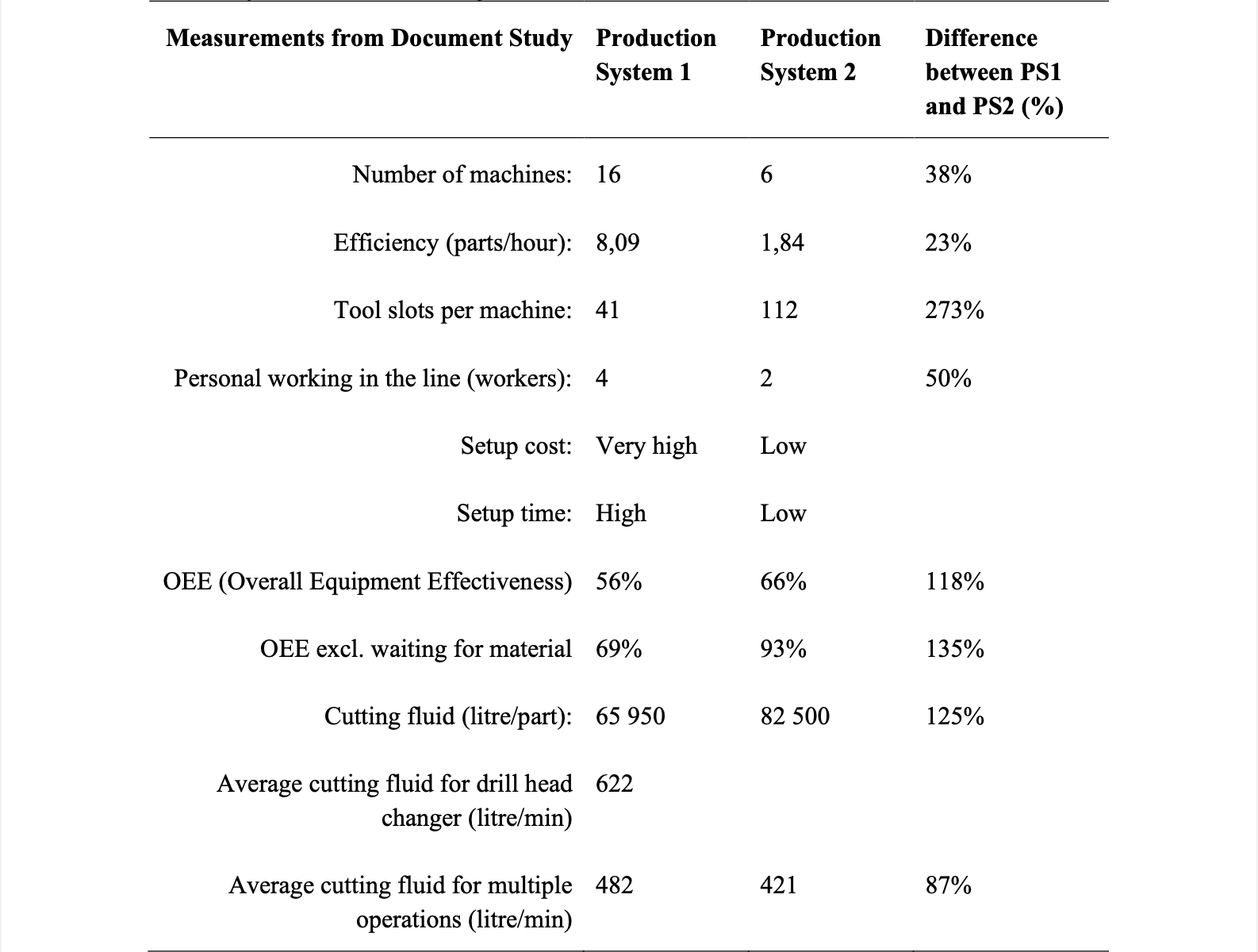

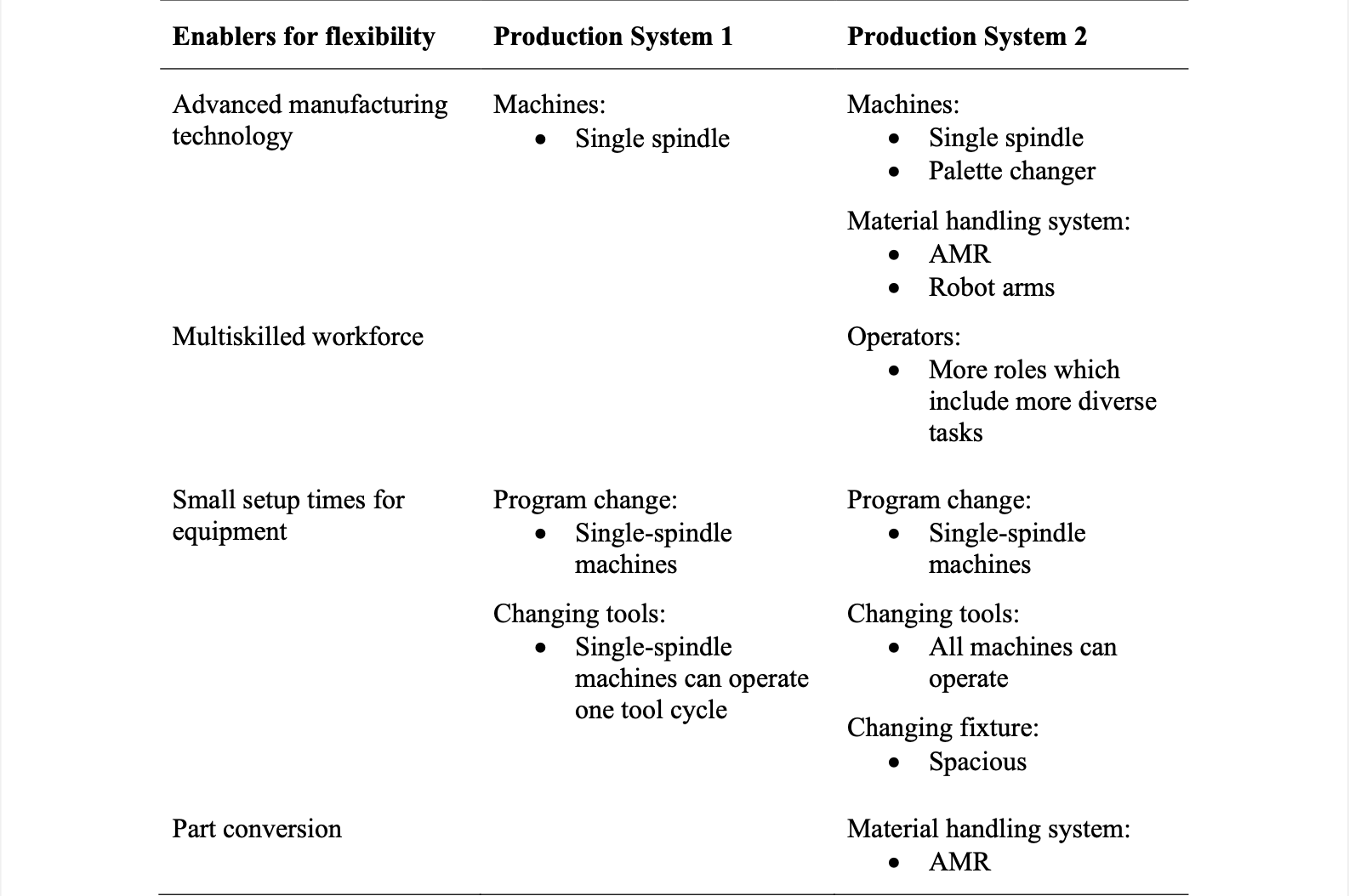

The study was conducted through a multiple-case study, where two production systems were compared in terms of product flexibility and sustainability. The comparison was conducted through the use of interviews, observations, and document studies. Furthermore, the key findings of the study consist of the role of product flexibility, including influencing flexibility types, enablers, trade-offs, and its relationship to sustainability. Four enablers were identified, along with two connecting trade-offs that are impacting product flexibility. Lastly, a framework is presented regarding the role of product flexibility for the automotive industry to cope with the green and electrical transition. The presented framework is to serve as guidance for organisations in the automotive industry to cope with the electrical transition.